Our Technology

Before Iris Dynamics...

Linear electric motors were inherently position or velocity controlled. What this means is that the motor driver was fed a command by a controller to either move to a specified position, move at a specified velocity, or a combination of the two. The downside to this behavior is that many industries could better utilize motors that react to outside forces, especially in human-machine interactive applications. The methods used to get a traditional motor to react to outside forces are cumbersome, introduce points of failure, and add control loop latency resulting in an unconvincing user experience.

So we came up with a solution...

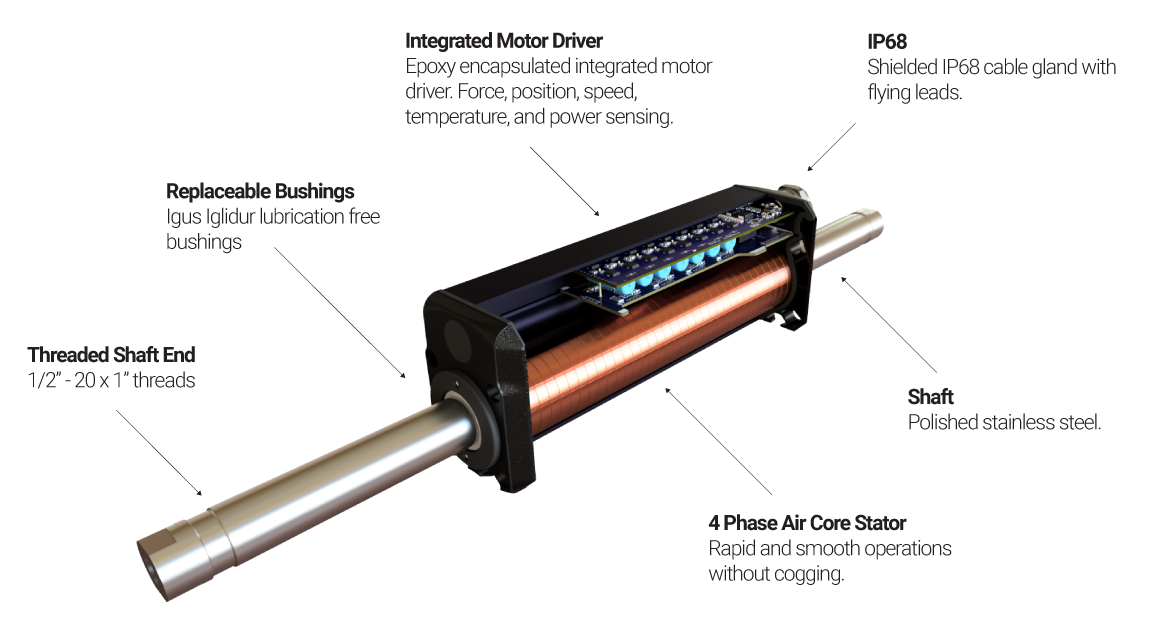

We have developed methods and tools to build force controlled motors that use generated magnetic fields produced by electromagnetic coils in the motor housing to impart Lorentz force onto permanent magnets contained within a shaft, rotor, or other object.

This design contains just a single moving part.

This increases reliability and lowers maintenance requirements. Proprietary magnetic geometries, software, and the elimination of any gearing means there is zero backlash and no cogging or grain felt by the end user regardless if the motor is being backdriven or not. The motors are small in form and consume much less power than competing technologies allowing for installation in smaller spaces with simpler, more economical, electrical & HVAC infrastructure.

Most importantly, as inherently force controlled motors, they sense their own force output and thus they can feel when a user imparts a force onto them. Control loop times of less than 1ms allow the motor to respond to these forces or other inputs nearly instantaneously while low friction contactless characteristics permit the resolution of that response to be on the scale of milligrams.

The result is an affordable and efficient motor that performs extraordinarily quick and precise movements while remaining silent.

Why choose our motors?

Force Controlled

Our motors are inherently force controlled which means they can be commanded to exert a specific level of force directly. Other motors use a novel arrangement of load sensors and amplification circuits to achieve a similar functionality. The result control loop times as long as 100ms-200ms. Our force controlled motors feature control loop times of less than 1ms. A by product of this is that the motors can feel force imparted upon them (a user’s input, for example) and react accordingly. This makes our motors ideal for VR and AR applications.

Simplicity via our 'All-in-One' approach

All our motors are fully integrated solutions with force sensing, position sensing, drivers, and logic built right into each unit. There is no need to purchase and install any additional hardware to get your project up and running. Characterization of the sensors is achieved during manufacturing which facilitates a smoother installation. A selection of communications and data logging options are available out of the box to suit each customer’s requirements.

Realism in Human-Machine Interaction

Our motors deliver force without any cogging. The design allows the shaft to slide freely within the stator without producing any unwanted forces due to induced currents. Some competing motors , for example, produce significant eddy currents which manifest as spikes of uncommanded force output when moving the shaft. The result is that a user feels periodic resistance (cogging) which is not consistent with the experience the motor is attempting to simulate. Our design also provides excellent force fidelity through the entire stroke of the shaft eliminating any grain. The result is that these motors deliver the smooth motion required for camera or sensor stabilization and real immersion in simulation or other human-machine interaction implementations.

Low Voltage

All our motors operate using low DC voltage which suits applications in which power can most conveniently be delivered by battery. Additionally this feature makes for a much easier connection to grid power by not requiring any special infrastructure beyond standard AC power outlets.