About Us

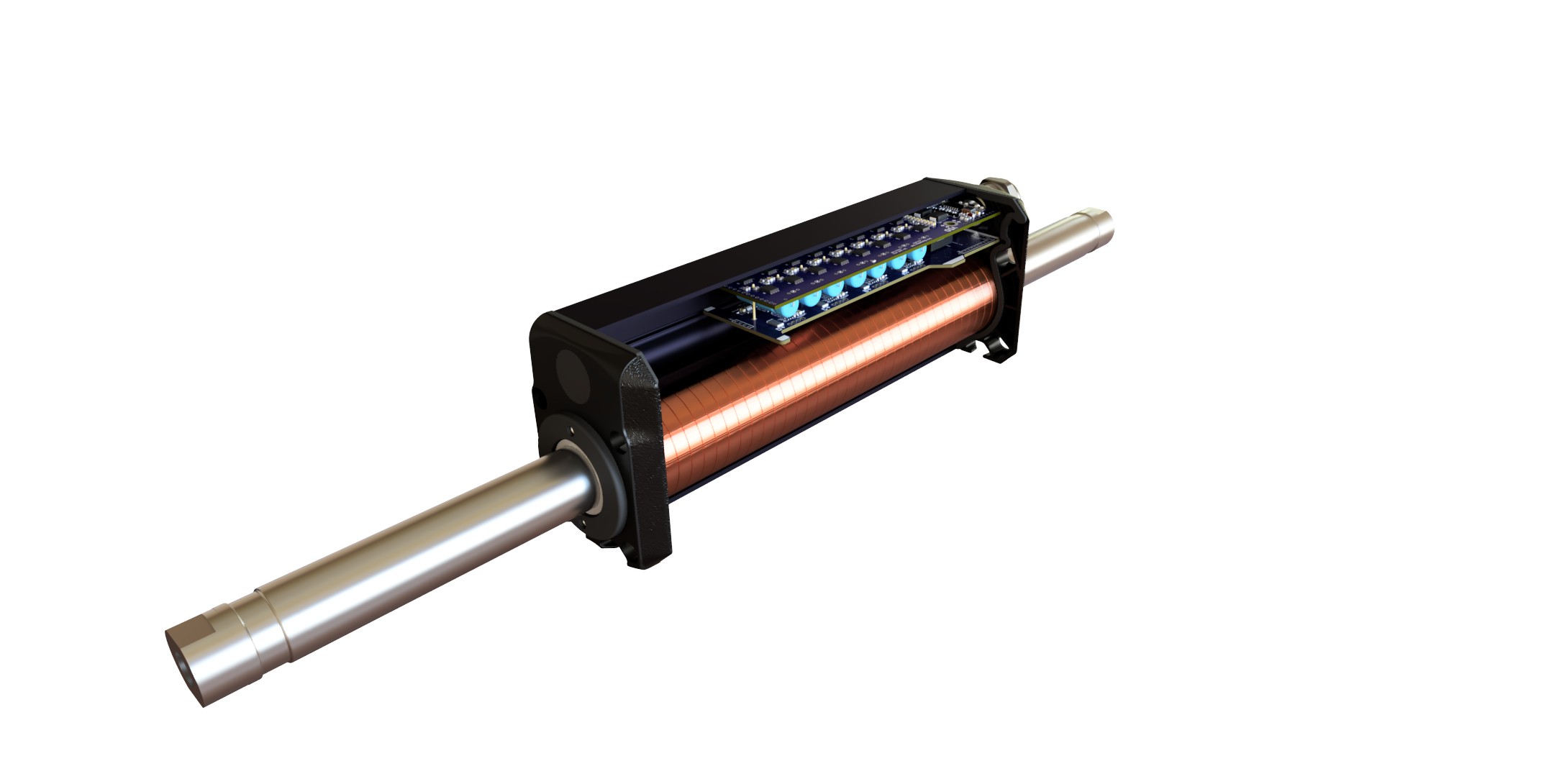

Iris Dynamics Ltd. is a technology business based in Victoria, British Columbia that develops and manufactures ISO 9001:2015 certified efficient intelligent linear electric motors

Our force-controlled motors are in use across many industries including aerospace, mining, testing and measurement, industrial automation, and VR simulation and entertainment.

Iris’s technology provides high efficiency, superior positioning performance, precise force-control, installation simplification, industrial ruggedness, and high lifetime.

Our team of skilled application engineers and sales professionals look forward to helping you bring idea to reality.

Our products are all manufactured at our facility in Victoria, British Columbia. When possible, we source our components from North American suppliers.

Our Story

Iris Dynamics Ltd. is born! Always located in Victoria BC, Iris was created to bring innovation to the aviation training industry.

A successful KickStarter campaign helps launch The Dragonfly™ Flight Yoke, our first product.

Our motors were used to bring more immersion to the steering system of the bobsled experience at the Richmond Speedskating Oval. Check out the video about the ride here.

Focus moves away from consumer products to B2B sales of our smart linear motors.

Our innovative motor technology matures as we develop and launch our first standard product, the DCA Series linear electric motor.

Our first major deployment of standard motors in a theme park attraction.

The ORCA Series intelligent linear electric motor officially launches with applications in industrial automation, VR and training, aerospace and defense, and more.

Some of Our Customers

Mission

We are the advanced motion control systems innovator that provides the highest precision force feedback and control loading linear motor systems for vehicles, training, fixed location entertainment, factory automation, robotics, and remote control. Our equipment, like our business, is built with rugged honesty and integrity.

Vision

To transform how machines and humans interact and to bridge the physical gap between muscle and motor with smarter linear motors.

Partner With Us

As we provide focused, technical solutions to modern problems, we're always on the lookout for new integration partners and OEMs that understand their markets and want to build themselves a competitive advantage using a modern approach to force and motion control.

Our team is highly motivated to provide training and engineering support to firms looking to become experts in Linear Motors, force control, and data collection. We're here to meet in person or virtually, walk through our technology's strengths and weaknesses, and equip our partners with the information and equipment they need to successfully deploy Iris Dynamics solutions.

Interested in a partnership?

Be in touch to speak with our sales team who will set up a call to discuss what working together looks like and the benefits it brings.