- October 24, 2022

Silence In Robotic Actuators and Systems

The Quest for Silence in Robotic Systems

The electrical hum and resonant vibrations of robotic systems can be extremely disruptive to users and applications, especially if it is a prolonged exposure. Despite continuous advances in actuator technology, there are very few systems that can claim to be silent.

Silent actuators are especially valuable in areas where noise either reduces operator concentration, eliminates immersion in a virtual environment, interferes with sensitive applications or instruments, or just adds to an already noisy work environment. There is a constant drive to innovate in the world of robotics, and a system that can operate silently will always be more impressive and sought after than one that cannot.

Dynamics’ Linear Motors Are Nearly Completely Silent

What causes noise in an electric actuator?

There are various causes of sound in an electric linear actuator and each type of electric actuator has a different source of sound. Some of which are listed below:

- Aerodynamic Noise – Noise caused by the cooling fan blades and is typically the main source of noise. This is only an issue on large AC motors that are used in applications with high speed and torque requirements.

- Mechanical Noise – Noise caused by misaligned shafts, worn bearings, motor-mounting factors and noise created by meshing gears. This is typically an issue in stepper and servo motors.

- Harmonics – Noise within electric motors can be caused by waveform resonance.

What are the advantages of silent linear actuators?

Silent robotics are highly sought after in the consumer product market. This is due to the effect created when a robot moves without any indication of how it is achieving the movement. A noisy motor breaks one’s immersion and awe of a robot or automated system.

Some key advantages of a silent linear motor are:

- Increased immersion in virtual reality (VR) training or entertainment environments.

- Less disruption in work environments.

- Increased situational awareness of other louder system components.

- Increased adoption in noise-sensitive applications (laboratories, recording studios, etc.).

- More energy-efficient systems.

- Less fatigue in humans sharing space with robots.

How do magnetic force feedback actuators reduce noise?

Magnetic force feedback actuators operate on a completely different set of principles than typical actuators such as servo controlled ballscrews, pneumatic, electric induction motor or even hydraulic systems. Their electromagnetic mode of operation allows for extremely silent operation as there are no mechanical components meshing and interacting with each other.

In most applications there is also no need for active cooling. This results in a system that is extremely quiet, i.e. as low as 20dB (or in some applications even lower).

An ORCA™ Series Linear Motor

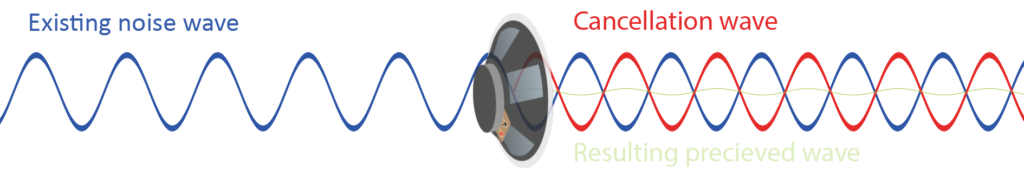

Furthermore, the kind of precise control afforded by an electromagnetic actuator allows noise reduction via the dynamic modulation of waveform shapes to account for acoustic resonance and torque ripples. These effects can be monitored and actively removed through various integrated software algorithms. This is very similar to the concept used in active noise cancellation headphones. This approach can respond to changes in the system in fractions of a second to adapt and account for noise. This is far removed from standard waveform shaping as not only is the waveform dynamically adjusted but so is the waveform shape.

Applications for silent robotics.

The number of uses for silent robotics is almost equal to the number of uses for normal robotics. This is because it is always desirable to reduce the overall sound generated by any mechanical system. Some of the more obvious uses of silent actuator technology are listed below:

The number of uses for silent robotics is almost equal to the number of uses for normal robotics. This is because it is always desirable to reduce the overall sound generated by any mechanical system. Some of the more obvious uses of silent actuator technology are listed below:

- Gaming & Virtual Reality (VR) – The noise from actuators can very quickly ruin human immersion in a virtual reality system. In a training environment, immersion is vital to the effectiveness of the program.

- Home Automation – The allure of a fully automated home will soon be lost if there is a constant droning in the background caused by the various actuators.

Silence is Critical for Immersion in VR Applications

- Medical Applications – Medical tools in hospitals such as electric lift beds and instrument racks, if excessively noisy, could cause distraction and discomfort for both the medical professionals and the patients.

- Cinematography & Recording Studios – In these environments it is critical that any equipment be as silent as possible to reduce time spent on post-recording editing to remove or mask nuisance sounds.

- Laboratory Applications – Laboratory equipment that is measuring sound or very small vibrations can be adversely affected by loud equipment.

- Robotics in Defence – Noisy systems in military applications can pose a significant risk to troops who are attempting to stay concealed or focused.

- Robotics for Wildlife – Recording and documentation of wildlife needs to be as clandestine as possible to reduce undue stress placed on the animals.

With the increased visibility of automated systems in our everyday lives, the use of silent actuators will become all the more valuable as a way to ease the transition to the age of automation. As these automated systems adopt silent motor technology their integrations will be as unobtrusive as possible.

Learn more about the ORCA Series silent linear motors here.