- November 4, 2025

ORCA™ Motor Powered Active Spring Damping Platform in Neonatal Transportation Systems

A Project In Collaboration with the National Research Council (NRC), Children's Hospital of Eastern Ontario (CHEO), and Carleton University

Neonatal transport is a vital lifeline, bridging fragile newborns to the advanced care of Neonatal Intensive Care Units (NICUs) and ensuring their safe return to local hospitals when recovery allows. However, the journey itself presents additional risks. Every movement matters when a newborn’s life is on the line; even the smallest vibration may have lasting consequences. Exposure to whole-body vibration (WBV), noise, and movement-induced instability can have serious physiological ramifications for neonates. Recognizing the need to characterize, develop better systems, and ultimately mitigate these risks, the NRC has been collaborating with Carleton University and CHEO. Working on a high-impact project with the NRC, sponsored by Innovation, Science and Economic Development Canada, Iris Dynamics’ RAVEN six-degrees-of-freedom (6DoF) system is being evaluated for its potential to enhance neonatal safety during ground transport. The goal is to develop and validate technologies capable of simulating and responding to the complex, multidirectional motion profiles encountered during neonatal ground transport. This article explores how the RAVEN-6DoF Platform Solution, powered by Iris Dynamics' ORCA Series Smart Linear Motors, enables active damping of motion in real time before it reaches the incubator. It also discusses some of the clinical challenges identified during the research.

Definitions

| Neonate | A neonate is also referred to as a newborn infant, aged 4 weeks or younger [1]. In clinical research, neonates are considered highly vulnerable due to their underdeveloped physiological systems. |

| Neonatal Transportation | The process, workforce, resources, and quality of care involved in transporting neonatal infants to and from one healthcare facility to another, often to or from a neonatal intensive care unit (NICU) [2]. |

| Isolette | A self-contained, clear acrylic chamber where the neonate resides during transport. |

| Whole Body Vibration | Vibration from a machine and or vehicle that is transmitted through and experienced by the entire body [3]. |

| 6-Degrees-of-Freedom | The ability of an object to move freely in a three-dimensional space, encompassing three translational movements (forward/backward, left/right, up/down) and three rotational movements (yaw, pitch, roll) [4]. |

| Force Density | The amount of force an actuator can generate relative to its size or weight. High force density is critical in applications where compact and powerful motion control is required. |

| Latency | Latency in the context of a control system is the delay between when a system detects a stimulus and when it produces a corresponding response. Low latency is essential for real-time control and effective vibration suppression. |

The Clinical Challenge: Neonatal Transport Risks

.png?width=1750&height=750&name=NRC%20Horizontal%20Photos%20(2).png)

Neonatal Transportation Process

Neonatal transport plays a vital role in ensuring that critically ill infants can access tertiary care and that stabilized patients can return to their local hospitals for continued treatment. Transport modalities include fixed-wing and rotary-wing aircraft, ground ambulances, and stretchers. A significant portion of the collaborative research project involving the NRC focuses specifically on ground transport, which poses unique challenges. During transit, neonates face environmental stressors such as vibration, noise, and thermal instability, all of which can disrupt physiological stability and increase the risk of adverse outcomes. While transfers are essential to access the appropriate level of neonatal intensive care required, the transport environment is affected by factors such as vehicle motion (vibration, acceleration, cornering, and uneven terrain), as well as exposure to high noise levels and temperature fluctuations.

Research Objective

To address the risks posed by vibration and noise during neonatal transport, the NRC has participated in a multi-year research program aimed at characterizing the biomechanical environment experienced by neonates during ground ambulance transfer. The research spans a comprehensive series of experiments, progressing from laboratory-based testing on individual components, such as the isolette, to full-system evaluations that include the stretcher, incubator, and vehicle chassis. This work supports the development and evaluation of mitigation strategies designed to minimize harmful exposure to vibration and noise.

Effects of Vibration and Noise on Neonates

Many studies have investigated the effects of excessive vibration and noise on neonates during transportation, revealing a range of potential complications. Reported consequences include increased blood pressure and heart rate, motion sickness, vomiting, elevated intracranial pressure, and movement-induced stress [6]. These outcomes are primarily associated with two critical environmental factors: whole-body vibration and acoustic exposure.

Whole Body Vibration

One of the most pressing challenges during neonatal transportation is managing whole-body vibration (WBV), particularly the sustained exposure to complex, multi-directional vibrations³. These vibrations span a wide range of frequencies and amplitudes, varying dynamically with road conditions, vehicle motion, and structural coupling within the transport system. During ground transport, dominant vibration frequencies can range from 9 to 10 Hz [7], which is uncomfortably close to the natural resonance range of the adult human body (5 to 20 Hz) [8]. The effects on neonates are particularly concerning, with research showing that elevated WBV is associated with decreased heart rate (p < 0.05). This decline in heart rate reflects autonomic nervous system disruption, a response that can indicate heightened stress or compromised physiological regulation in vulnerable infants. Reduced heart rate variability and lower heart rates have been linked to poorer psychological and physiological outcomes (p < 0.001 and p < 0.01, respectively) [6]. Even on well-maintained roads, WBV can compromise a neonate’s physiological stability.

.png?width=1750&height=750&name=NRC%20Horizontal%20Photos%20(1).png)

Measured vibration levels during neonatal ground transport often exceed the recommended adult exposure threshold of 0.31 m/s² [10], and there are currently no established standards for infants. Compounding this concern is the presence of resonant amplification within the transport system. Vibration-induced motion has been shown to interact with key components such as the incubator pan, amplifying motion at frequencies between 8 and 10 Hz [7]. These frequencies are particularly problematic because they align with the natural resonant frequencies of both the neonatal skull and thoracic cavity, intensifying the internal stress experienced.

Noise

Noise levels during neonatal ground transport pose another serious physiological challenge. Measurements have shown that sound levels within the isolette commonly exceed 70 dBA, with incubator interior levels ranging from 55-80 dBA [11] during transportation. These noise levels far surpass the 45 dBA [12] threshold recommendations by the American Academy of Pediatrics (AAP) for neonatal intensive care environments. Exposure to elevated noise has been directly associated with increased heart rate (p = 0.05) [6] and greater physiological stress in neonates. Loud and sudden auditory stimuli are also implicated in reduced oxygen saturation and disrupted sleep patterns, further compounding the risk for vulnerable preterm infants. Despite this, there is currently no regulatory standard specific to noise exposure limits for neonates during transport.

Key Design Challenges: Simulating and Responding to Complex Multidirectional Motion

A central challenge in evaluating neonatal transport system design is the need to accurately simulate and assess the complex, multidirectional motions experienced during ground ambulance transport. Neonates are highly sensitive to environmental stressors, and both vibration and noise during transport have been linked to adverse physiological outcomes, as described above. One of the main objectives of the neonatal project conducted by Carleton University, CHEO, and the NRC is to develop a robust testing methodology that not only replicates real-world road conditions but also captures the coupled linear (heave, surge, sway) and rotational (pitch, roll, yaw) motion profiles encountered during transport across various road types. While standard vibration tables or incubator-only tests are constrained by single-axis excitation and may not adequately replicate these complex dynamics, CHEO’s evaluations on the six-degrees-of-freedom motion base included coupled, lower-frequency motions with the largest amplitudes, and the NRC’s post shaker captured the additional effects of roll and pitch induced by terrain irregularities.

A central challenge in evaluating neonatal transport system design is the need to accurately simulate and assess the complex, multidirectional motions experienced during ground ambulance transport. Neonates are highly sensitive to environmental stressors, and both vibration and noise during transport have been linked to adverse physiological outcomes, as described above. One of the main objectives of the neonatal project conducted by Carleton University, CHEO, and the NRC is to develop a robust testing methodology that not only replicates real-world road conditions but also captures the coupled linear (heave, surge, sway) and rotational (pitch, roll, yaw) motion profiles encountered during transport across various road types. While standard vibration tables or incubator-only tests are constrained by single-axis excitation and may not adequately replicate these complex dynamics, CHEO’s evaluations on the six-degrees-of-freedom motion base included coupled, lower-frequency motions with the largest amplitudes, and the NRC’s post shaker captured the additional effects of roll and pitch induced by terrain irregularities.

This work, conducted independently of the Iris/ISED project, involved the NRC’s use of a full-vehicle, tire-coupled road simulator capable of recreating both the translational and angular accelerations recorded during real on-road events such as pothole strikes, speed humps, and railway crossings. However, generating drive files that accurately reproduce real-world responses required meticulous calibration, iterative testing, and close attention to variables such as ballast weight, sensor alignment, and suspension behaviour. This multidimensional fidelity was essential not only for characterizing the transport environment but also for evaluating proposed vibration mitigation strategies under repeatable, high-fidelity conditions.

The Technology Solution: RAVEN-6DoF Motion Platform

To investigate the vibration mitigation achievable with active damping, the NRC evaluated the RAVEN-6DoF Motion Platform. This compact, low-power, six-degrees-of-freedom (6DoF) actuation system is powered by ORCA motors. Engineered for environments where both space and noise constraints are critical, the RAVEN-6DoF is designed to provide real-time active stabilization across translational and rotational axes. This capability enables not only the simulation of real-world motion but also fine control over its suppression and shaping. At the core of RAVEN’s performance is its use of ORCA motors. These electromagnetic actuators offer direct-drive motion with submicron resolution, zero backlash, and silent operation, making them especially well suited for sensitive medical environments. Unlike traditional mechanical systems that introduce friction, lag, or acoustic interference, ORCA motors deliver clean, high-force actuation that meets the precision demands of neonatal testing.

To achieve the required dynamic range and isolation performance, the RAVEN-6DoF test bed employed a stacked platform configuration. Two modular RAVEN-6DoF platform stages were mounted on top of each other. This mechanical layering provided enhanced vibration attenuation and enabled compound motion control, with one stage absorbing gross vehicle movement and the other delivering precise micro-adjustments at the isolette interface. The platforms consume little power and run on DC batteries, keeping the system compact and energy efficient.

The RAVEN-6DoF platform used a combination of sensors, feedback loops, and Proportional-Integral-Derivative (PID) control algorithms to achieve damping. High-frequency data from accelerometers and inertial sensors were processed in real time to generate counteracting motor commands, with onboard processors issuing adjustments at sub-millisecond intervals.

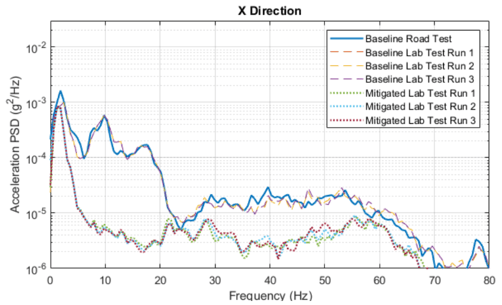

Graph highlighting the reduction in acceleration detected in one test axis

Smart Actuation in Action: Software Based Damping

At the heart of the RAVEN-6DoF platform’s performance is the ORCA motor smart actuation architecture, which integrates high-force-density linear magnetic drives with embedded sensors and onboard controllers. This design allows for low latency and real-time responsiveness, enabling the system to detect microvibrations and subtle motion deviations, and to respond within milliseconds using precisely tuned counteractive forces.

Unlike traditional active damping systems that rely on Inertial Measurement Units (IMUs) or bulky mechanical linkages, ORCA motors achieve vibration suppression through real-time position tracking and control-loop-based force application. The system leverages the derivative gain component of the position controller to apply a resistive force proportional to the rate of change in motion. This functions as a software-based damping layer, allowing the actuator to respond dynamically to high-frequency vibrations by effectively “pushing back” in real time, without requiring an external IMU. By eliminating the need for an IMU, the system reduces both complexity and potential points of failure while significantly lowering costs. High-precision MEMS IMUs typically range from $1,000 to $10,000, and fibre optic gyroscope (FOG) IMUs can cost between $10,000 and $100,000 [13], depending on accuracy and application requirements. By leveraging ORCA’s integrated position-sensing and real-time control capabilities, the RAVEN platform achieves precise motion tracking and vibration suppression without the added expense of these components.

This approach enables the platform to suppress motion across all six degrees of freedom, including lateral, longitudinal, vertical, and rotational axes, without adding noise, friction, or system complexity. High force density is essential in this context, allowing each actuator to deliver significant corrective force within a compact footprint. This capability supports multi-axis actuation while maintaining a lightweight and modular system design. Low latency is equally critical in this application, as it directly affects how quickly the system can respond to a detected disturbance. Direct-drive electromagnetic actuation eliminates mechanical lag from gearboxes or linkages, while embedded position sensors and onboard motor control electronics prevent communication delays with external systems. High-bandwidth control loops process feedback and issue force commands at kilohertz frequencies. This level of responsiveness allows the system to apply real-time software damping before vibrations propagate throughout the platform and to adapt immediately to rapidly changing motion profiles.

Critical Features

| Low Latency Response | Millisecond-level responsiveness enables dynamic vibration suppression and real-time control. |

| No IMU Required | Integrated force and position sensing dampens motion, removing the need for inertial sensors or external feedback devices. |

| Integrated Position Sensing | High-resolution magnetic encoders provide precise, noise-free positional feedback without drift or the need for recalibration. |

| High-Fidelity Motion Modelling | Accurately replicates complex, multi-axis disturbances with biomechanical relevance and consistent repeatability. |

| Local Data Processing | Onboard processing of sensor inputs enables ultra-fast control loops without reliance on external systems. |

| Stackable Platform Architecture | Modular design separates gross and fine motion stages, improving overall system performance and reducing vibrational noise. |

Broader Implications and Scalability

The integration of two RAVEN-6DoF platforms, each powered by ORCA motors, provided NRC researchers with more than just a tool for high-fidelity neonatal transport simulation. One platform was configured to investigate the impact of active vibration damping in a ground ambulance, while the second was used to conduct vibration tests on a transport incubator in six degrees of freedom (6DoF). By enabling precise, real-time control of vibration and motion in a compact, quiet, and modular form factor, the technology allowed the research team to move beyond conventional analysis and explore conditions that had not previously been experimentally validated.

Looking ahead, the platform’s adaptability highlights its potential for broader deployment in other high-sensitivity environments, including airborne incubator transport, mobile surgical units, and medical logistics for military or humanitarian missions. In each of these scenarios, patient safety and motion stability remain critical priorities. As research and clinical teams continue to investigate the biomechanical impacts of transport, systems such as the RAVEN-6DoF Platform Solution serve not only as responses to current challenges but also as enabling technologies that open new avenues of discovery.

-1.png?width=1100&height=163&name=CTA%20Banners%20for%20Blogs%20(1)-1.png)